Practically all companies around the world are powered by an infrastructure built around delicate electronic components, highly sophisticated technological information systems, and computer software that allows system management and monitoring at the touch of a button.

But there’s something else that’s just as important, and is equally just as big a piece of the puzzle that makes sure that business keep moving along like a well oiled machine. It’s the system of pipes and tubes found in almost every industry imaginable. If a business has a building, then there’s most likely a piping infrastructure within it.

A necessary system to ensure the transport of liquids like fuel, oil, even drinking water, pipes require routine maintenance to prevent breakdowns or contamination of the material they’re transporting. And since replacing entire portions of pipe can be expensive and isn’t always the most feasible solution, specialty tapes are available to handle the special challenges of working with piping framework.

Anti-Splash and Spray Control Tapes

Leaking and spraying from pipes is never good, but it’s even more detrimental to those who work in the maritime industry. Confined spaces and close proximity of resources pose a threat of high amounts of damage should something go wrong, and deployment at sea can impact the access to medical care in the case of an accident.

The International Convention for the Safety of Life at Sea (SOLAS) has set forth rules that, when properly adhered to, help ensure the health and safety of those who work on maritime vessels. This includes installing preventative maintenance measures, and Anti-Splash and Spray Control Tapes are two of the most effective ways to meet SOLAS guidelines.

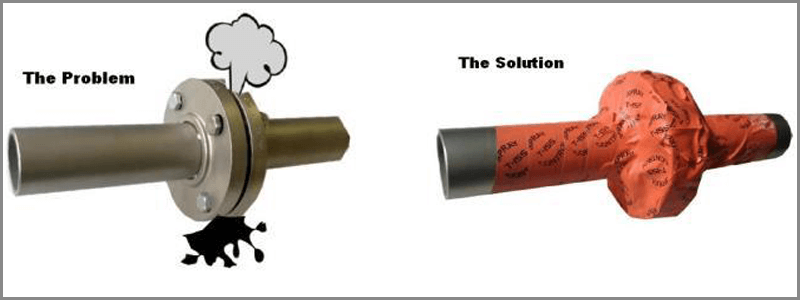

Both tapes work in essentially the same fashion, with the major determining factor on which to use in a particular situation dependent upon the type of liquid moving through the pipe. Tapes are applied around fittings and flanges, but can also be used over areas that have become weakened over time. When applying, tapes can be affixed in a way that re-directs liquid to areas where they can’t cause damage in the case of a rupture or leak.

When considering a purchase, be sure that the tapes are manufactured by T-ISS, an organization that has been creating high-quality tools for the maritime industry since 2003.

Anti-Corrosive Tapes

A business that relies upon metal pipes should expect some degree of corrosion to form over time. Occurring when metal undergoes oxidation, corrosion can lead to expensive repairs and create unsafe working conditions for employees.

Compounding the issue is when pipes are located underground, where routine maintenance and monitoring of these surfaces is usually not conducted regularly.

Anti-Corrosive Tapes add a protective layer to the top of any pipe, whether it be located above or below ground. Generally produced from either PVC or petrolatum, these tapes are wrapped around areas most susceptible to corrosion, including joints and connective fittings, and provide long-lasting protecting that resists moisture (even in underwater settings!).

A great benefit about using tapes for corrosion protection is that, unlike paints or other products, the tapes won’t have to be reapplied as often. They can also be used in areas that have already suffered minor amounts of corrosion.

Leak Prevention Tapes

If you’ve ever fixed a leaky pipe around the house, then you may have used a tape product to help stop the drip. Pliable silicone makes leak prevention tapes easy to work with, as they’ll adapt to most any fitting or surface. Since they’re non-porous, you don’t have to worry about any liquids passing through the tape itself, and it’s resilient to changes in temperature and most external elements.

Great for on-the-fly repairs, the small stature of these tapes make them excellent for creating non-slip handles on tools and for bundling of wires, ropes, and cords.

Identification Tapes

Not all industrial tapes are designed to address spills, sprays, and leaks. Identification tapes help mark pipes in order to increase their visibility, and can be just as beneficial as any of the other products discussed here.

Typically manufactured from materials that won’t fade or show damage easily, these tapes come in bright, vibrant colors in order to attract awareness. Color-coding helps workers know exactly what is moving through a particular pipe, and tapes displaying arrows on them can denote which direction the fluid is moving.

Identification tapes can also create a visual warning in the case of low-hanging pipes, which goes a long way in preventing accidental head injuries.

Safety by the Roll

While many of these tapes can help reinforce areas of weakness along pipes, it’s always best to make sure that they’re installed BEFORE any issues arise (and it never hurts to have a dedicated pipe repair kit on hand). All of the tapes listed above are created for their industry; that means they serve very specific purposes, unlike band-aid solutions like duct or electrical tape, which doesn’t adequately address the situation at hand.

Whether a business is located on water or not, there are special tapes available to reinforce and protect the piping system that powers it. Consider the specific needs of your own organization, and custom build your own toolkit of tapes.